ArcticWhite offers the BioMicroLab robotic platforms for tube handling, liquid handling, weighing, barcode reading, labeling, and more for tube racks with a wide range of tube/vial volume, height, and XY format.

Included in the offering are the XL Series of reliable, flexible and affordable robotic pick and place systems that automate critical sample management tasks such as organizing, reformatting and analyzing samples. They are standardized platforms with liquid handling, tube weighing, sample identification, verification, tube label printing and application, and capping/de-capping.

All of the BioMicroLab products are designed to provide fast sample processing, unattended operation, and robust sample management to eliminate the problems with manual, repetitive tasks.

Tube & Vial Handling Platforms

The XL20, XL9 Tube Handler Systems, and the XL100 and XL200 Tube & Vial Handler Systems are fully compatible with LIMS systems, easily integrating with your laboratory’s high performance needs and multiple labware formats.

Showing all 4 results

-

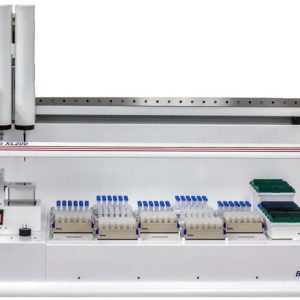

XL20

Twenty Rack Capacity for 96 Well Tube Formats

Features

- Automates collection of tube 2D barcode, weight, volume, and DMSO hydration

- Decode 2D barcode with integrated camera

- Weighs sample with 0.1mg balance option

- Scans sample volume in capped tubes (with LevelCheck option)

- Scans sample DMSO hydration with TubeDowser

- XL LabelPro to print and/or apply – NEW!

- Small 28.5” x 21” footprint

Automation Benefits

- 18 to 20 tube rack deck provides hours of “walk away” time

- Same procedure for processing small and large sample sets

- Sample data output in CSV files for Excel or LIMS

- Re-arrays up to 500 tubes per hour

- Weighs up to 300 tubes per hour

Operation

- XL20 software has pre-set load & go sample processing modes

- Worklist, Tare/Gross weighing, & Data collection modes

- Worklist mode allows re-array of small and large sample sets

- Software guided deck loading streamlines operation

Throughput

- 700 tubes per hour – sort only mode

- 500 tubes per hour – sort and 2D scan mode

- Over 300 tubes per hour – sort and weigh mode

- 150 – 180 tube per hour – sort and label

Compatible 96 well tube format labware

- Micronic

- Thermo / Matrix / ABgene

- Corning

- FluidX

- Others

Configurations

The XL20 is designed for use with 96 well tube rack samples and your model can be configured with the features you need, including:- Automated Balance

- 2D Barcode Reader

- LevelCheck (for volume detection)

- XL LabelPro for print and apply tube labeling

- Cool Room Configuration

Capacity by Model

- XL20 with 2D reader (20 rack capacity)

- XL20 with 2D reader and balance (18 rack capacity)

- XL20 with 2D reader and LevelCheck (19 rack capacity)

- XL20 with 2D reader, balance, and TubeDowser (17 rack capacity)

- XL20 with 2D reader and XL LabelPro (18 rack capacity)

Twenty Rack Capacity for 96 Well Tube Formats ...

Read More -

XL9

Nine Rack Capacity for 96 Well Tube Formats

Capacity by Model

- XL9 with 2D reader (9 rack capacity)

- XL9 with 2D reader and balance (7 rack capacity)

- XL9 with 2D reader and LevelCheck (8 rack capacity)

- XL9 with 2D reader, balance, and TubeDowser option (6 rack capacity)

- XL9 with 2D reader and XL LabelPro (7 rack capacity)

Features

The XL9 has all the Features, Automation Benefits, Operation, Throughput, Labware Compatibility, and Optional Configurations of the XL20.

To review the Features and Benefits of the XL20, click here.Nine Rack Capacity for 96 Well Tube Formats ...

Read More -

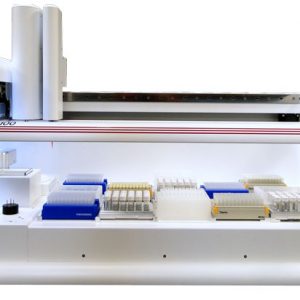

XL200

Thirty Rack Capacity for Tube and Vial Formats

Features

- Re-arrays a range of vial sizes and 96 well tube rack samples

- Automated 4-place balance records sample weight (5-Place Balance is an option)

- Records sample vial 1D or 2D barcode & rack ID barcode

- Bench top 48″ x 30.5″ footprint

Automation Benefits

- 30 rack deck provides hours of “walk-away” time

- Same procedure for processing small and large sample sets

- Sample data output in CSV files for Excel or LIMS

- Re-arrays 450 vials per hour

- Weighs 180 vials per hour

Operation

- XL200 software controls several load & go sample processing routines

- Routines include: Tare/Gross weighing, weight and 2D and 1D barcode collection

- A worklist mode allows re-array of large sample sets

- Barcoded deck streamlines loading sample racks

Compatible 96 tube format labware

- Micronic

- Thermo / Matrix / ABgene

- FluidX

- Corning

- Others

Compatible sample vials

- Vacutainer

- Greiner Bio-One

- 4mL glass

- 2mL plastic tube

- Others

Configurations

The XL200 deck holds 30 SLAS type tube racks or can be configured for a wide range of tube racks and vial trays. Your model can be configured with the features you need, including:- Liquid Handling

- 4-place Balance or 5-Place Mettler Toledo WXS Balance

- 1D and 2D Barcode Reader

- Capper / De-capper

- Cap Feeder

- Rack Transfer Station

- XL LabelPro to print and/or apply – NEW!

Thirty Rack Capacity for Tube and Vial Formats ...

Read More -

XL100

Twenty Rack Capacity for Tube and Vial Formats

Features

The XL100 has all the Features, Auotmation Benefits, Operation, Throughput, Labware Compatibility, and Optional Configurations of the XL200.

To review the Features and Benefits of the XL200, click here.Twenty Rack Capacity for Tube and Vial Formats ...

Read More