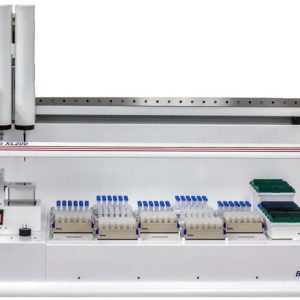

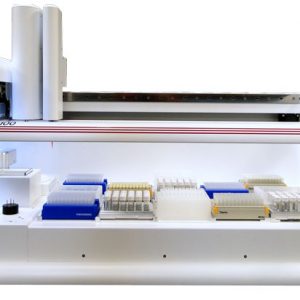

Twenty Rack Capacity for 96 Well Tube Formats

Features

- Automates collection of tube 2D barcode, weight, volume, and DMSO hydration

- Decode 2D barcode with integrated camera

- Weighs sample with 0.1mg balance option

- Scans sample volume in capped tubes (with LevelCheck option)

- Scans sample DMSO hydration with TubeDowser

- XL LabelPro to print and/or apply - NEW!

- Small 28.5” x 21” footprint

Automation Benefits

- 18 to 20 tube rack deck provides hours of "walk away" time

- Same procedure for processing small and large sample sets

- Sample data output in CSV files for Excel or LIMS

- Re-arrays up to 500 tubes per hour

- Weighs up to 300 tubes per hour

Operation

- XL20 software has pre-set load & go sample processing modes

- Worklist, Tare/Gross weighing, & Data collection modes

- Worklist mode allows re-array of small and large sample sets

- Software guided deck loading streamlines operation

Throughput

- 700 tubes per hour - sort only mode

- 500 tubes per hour - sort and 2D scan mode

- Over 300 tubes per hour - sort and weigh mode

- 150 - 180 tube per hour - sort and label

Compatible 96 well tube format labware

- Micronic

- Thermo / Matrix / ABgene

- Corning

- FluidX

- Others

Configurations

The XL20 is designed for use with 96 well tube rack samples and your model can be configured with the features you need, including:

- Automated Balance

- 2D Barcode Reader

- LevelCheck (for volume detection)

- XL LabelPro for print and apply tube labeling

- Cool Room Configuration

Capacity by Model

- XL20 with 2D reader (20 rack capacity)

- XL20 with 2D reader and balance (18 rack capacity)

- XL20 with 2D reader and LevelCheck (19 rack capacity)

- XL20 with 2D reader, balance, and TubeDowser (17 rack capacity)

- XL20 with 2D reader and XL LabelPro (18 rack capacity)